|

| Progress? Maybe! |

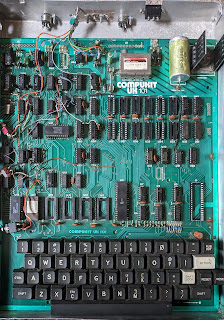

Last time, the next planned step was to remove all of the bodges and restore the machine to something resembling a "factory configuration". This aim has changed slightly: a lot of the bodges are gone but some remain:

- The 48x32 display mod was just too tricky to undo without a display to test it against.

- Similarly will leave the 300/600 baud and RS-232 mods until a later time.

- The monitor switch mod also stays until the EPROM has been verified to work.

So what has been done here?

- The piggybacked RAM and its decoding logic is history. New sockets were added where necessary.

- The 6522 VIA board is also gone.

- A new expansion socket was added to facilitate testing with a Logic Analyzer.

To replace the IC sockets I found the following tools essential:

- Soldering Iron and solder

- Desoldering pump

- Headband Magnifier

- Bench vise

Don't expect existing IC sockets to survive this process!

- Use the desoldering pump to remove most of the solder; this helps free some of the pins but others will probably remain attached.

- Gently lever the socket away from the board: it will likely break, leaving some pins in place.

- Desolder these one by one.

- Some VIAs will most likely remain at least partially full of solder. To clear them, mount the board vertically in the bench vise and heat each VIA from one side while applying the desoldering pump from the other. It may be necessary to fill the VIA with solder before attempting to clear it, counter-intuitive but it works!

- When inserting a new socket do not use force. If it doesn't go in easily, repeat step 4 until it does!

To desolder an unsocketed chip:

- Use the pump to remove most of the solder as before.

- With a small screwdriver gently push each pin until a click is heard. This means the pin is mostly free of solder.

- From the other side of the board, gently lever the chip away from the board. If it doesn't move, mount the board vertically as before, heat the pins on the chip side while applying the desoldering pump from the other. Repeat!

This all requires patience, and a steady hand!

|

| Flux pen, Desoldering braid and Pump |

I also ordered a flux pen and desoldering braid which should be as good or better as the desoldering pump. However I wasn't able to get good results with it. Perhaps my soldering iron isn't hot enough?

Adrian's Digital Basement has a great tutorial on this subject. He also has better tools than I do!